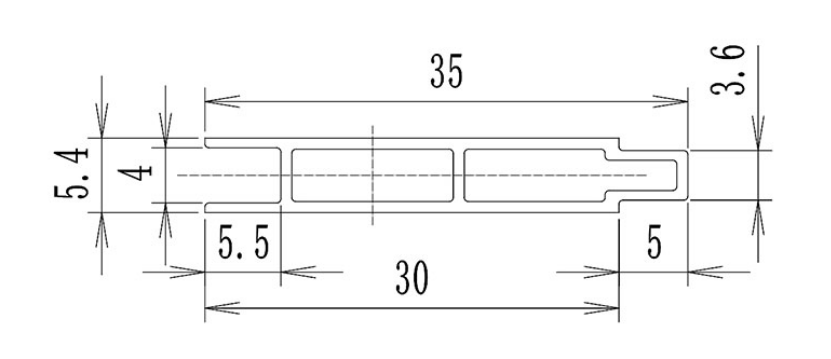

Parameters of spliced honeycomb laminate:

Model: GA28-19A-30

NW single weight: 170g (g)/ m (m)

PQ: 12 PCS (set)

Single root length L: 4 m (m)

Aluminnum Alloy 6005T6

The standard width of the special bottom plate combined with the main profile of the tray system is 50mm. It can be used together with GA28-17A-100 and GA28-19A-30 to obtain the required length and size.

This product is not allowed to be cut in the width surface. It is recommended that three sizes be matched to get the calculated size.

Aluminum honeycomb panel surface:

1, flat appearance, diverse colors, elegant and clean

Aluminum honeycomb panel, different specifications and sizes have high flatness, and has the advantage of not easy deformation, the panel is mainly made of fluorocarbon roller coated aluminum plate. Fluorocarbon roller coated aluminum plate is the most important point is the use of continuous roller coating process, the coating of aluminum plate is completed at one time, the product color free coating flow level is good, reliable quality, can keep the building exterior wall color bright for a long time. After a long period of sun and rain or industrial air pollution, it is obvious that the roller coated plate is cleaner and brighter than the spraying, and has good adhesion and weather resistance

2, decorative, easy to install, fast

Aluminum honeycomb panel bottom panel can be selected according to different requirements of different materials, such as aluminum plate, stainless steel plate, color steel plate, stone, curtain wall aluminum honeycomb panel is based on the site design size, in the factory processing. The plate is bent around, and then compound forming, and then punching the hanging ear and plate into a whole, so that the honeycomb hanging plate after forming is more firm. Full factory production, reliable quality, convenient installation, fast.