Please share the design requirements of the fluent strip accessories manufacturers

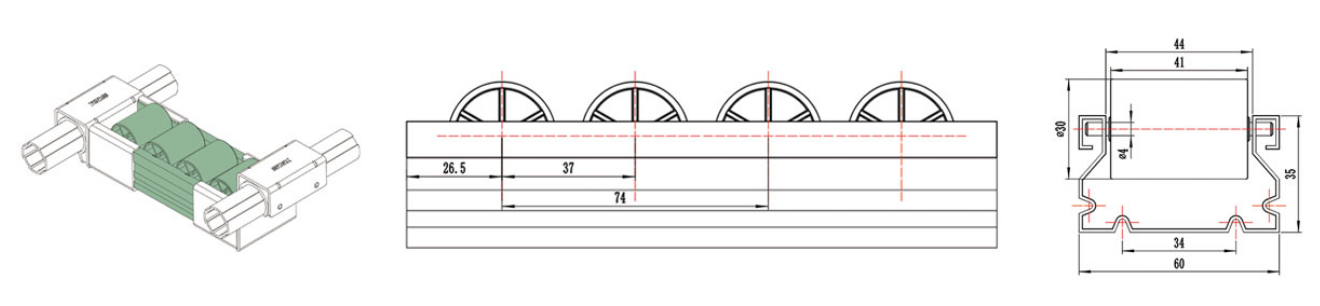

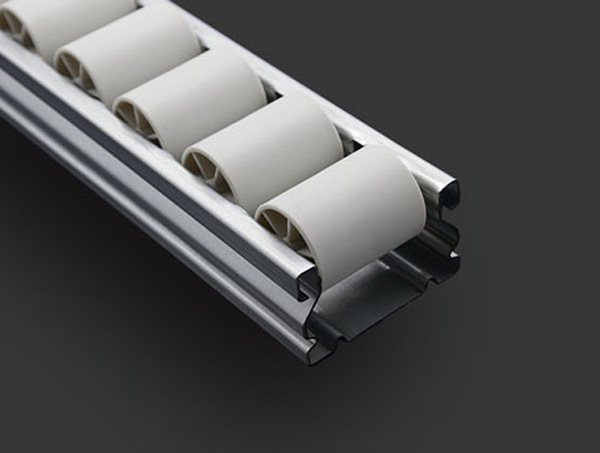

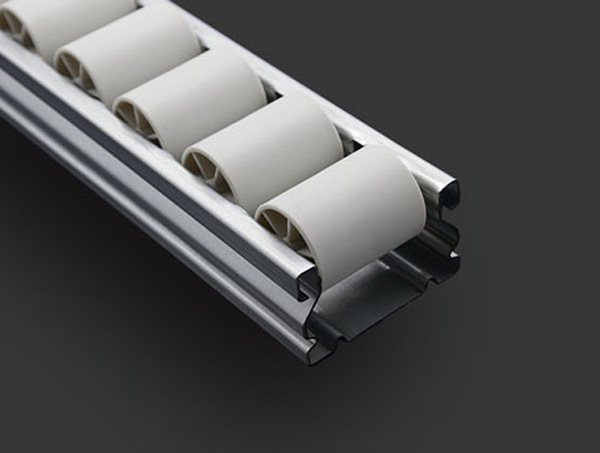

The guide strip is mainly suitable for storage, shelf supporting products, can be used as slideway, guardrail, guiding equipment, and the transmission action is very sensitive. The design of the flow bar needs to take into account the load and other problems. Now let the fluent strip accessory manufacturers introduce the design requirements of the fluent strip:

The flow strip is designed with load in mind, which can be strengthened by adding fulcrum connections and using plastic coated double roots in parallel.

In the design of the structure, it is determined that the main load is applied directly to the pipe rather than to the connecting member. Large horizontal distances can be set freely every 600 mm (depending on the concrete structure design of the gravimeter), the method of selecting blocks type components must have support columns and be perpendicular to the ground, and every 1200 mm, the vertical columns should be directly grounded.

For example, with casters, the chassis parallel structure should be double rod. Horizontal distance 600 mm, 30 kg single slide smooth, safe loading. The strength is stronger than covering several plastic tubes with a plastic cover from the chuck series, so the adhesive force must be the whole one and the connecting rod can be segmented in the choice of coated plastic tubes.

Slide the shelf width of each column (center distance) to be placed in the container width +60 mm; And the height of each layer is placed in the handbag height + 50mm. The inclined Angle of the chute is determined to be the exact position where the heavy material and the bottom handbag are relatively smooth, usually sliding 5 to 8 degrees, and the inclined Angle is small.