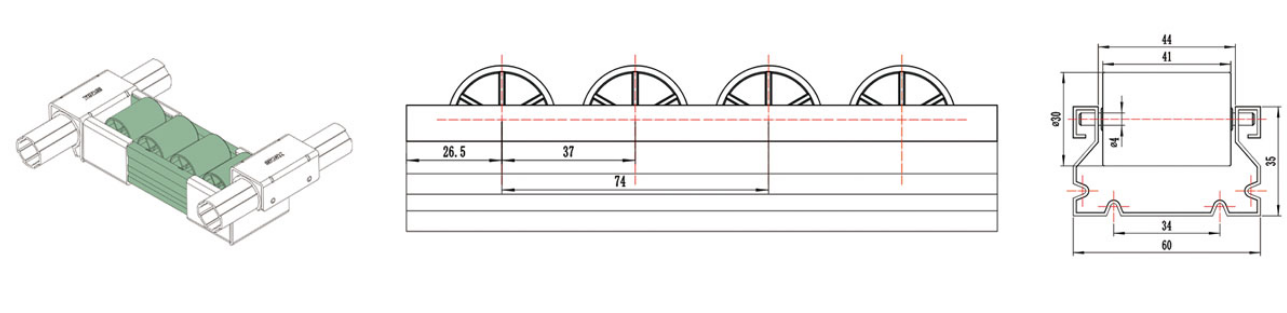

Fluency bar classification introduction:

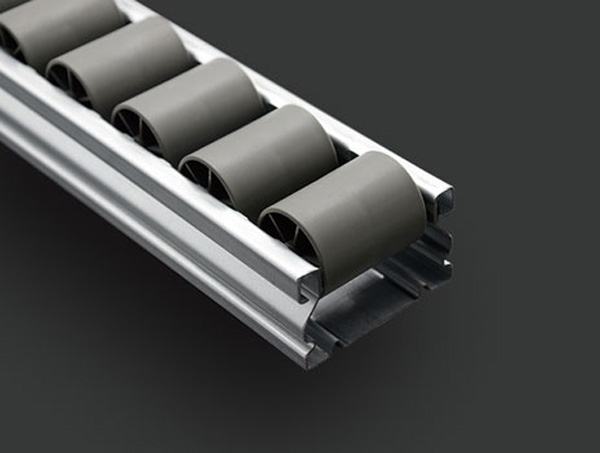

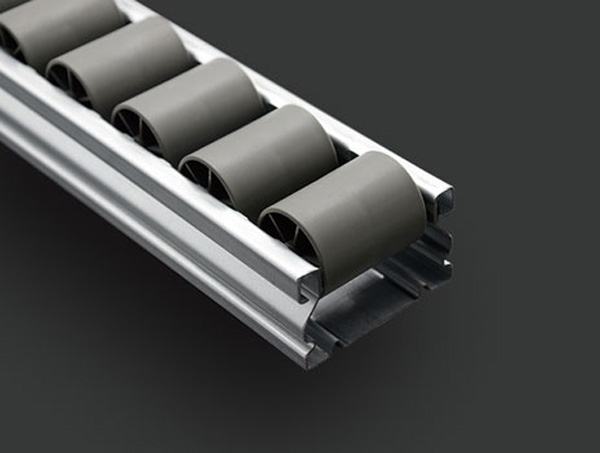

Fluent strip is mainly used for storage, shelf supporting products, can be used as slide, guardrail, guide device, flexible transfer. Conveying fluency can carry out horizontal, inclined and vertical transmission, but also can form a space transmission line, the transmission line is generally fixed. Conveyor conveying capacity, long distance, but also in the process of conveying at the same time to complete a number of process operations, so the application is very extensive.

Differential chain fluent strip: using special aluminum alloy profile as guide rail, with speed chain drag fixture plate as transmission medium. The flow strip adopts combined assembly mode, and the number of stations can be set according to the process requirements. The station is equipped with foot switch, power socket, station block, process drawing board, lighting, etc. The line body is equipped with lifting leveling machine, lifting rotating table, etc., so that the whole process can achieve automatic working state.

Plate chain fluent strip: the use of chain plate to pull the workpiece to do plane transmission movement, to achieve the purpose of production technology. The flow strip adopts combined assembly mode, and the number of stations can be set according to the process requirements. The station is equipped with power socket, toolbox, material box, etc., so that the whole process to express, orderly.

Plug-in fluent bar: the chain is used to drag the tooling trolley to run in a horizontal ring for workpiece assembly.