Plate directional casters are continuous working parts and play a very important role. However, long-term use will cause damage and have a certain impact on the stability of the machine. So regular inspection and maintenance is an essential part of the maintenance of industrial casters. Here are some ways to repair industrial casters.

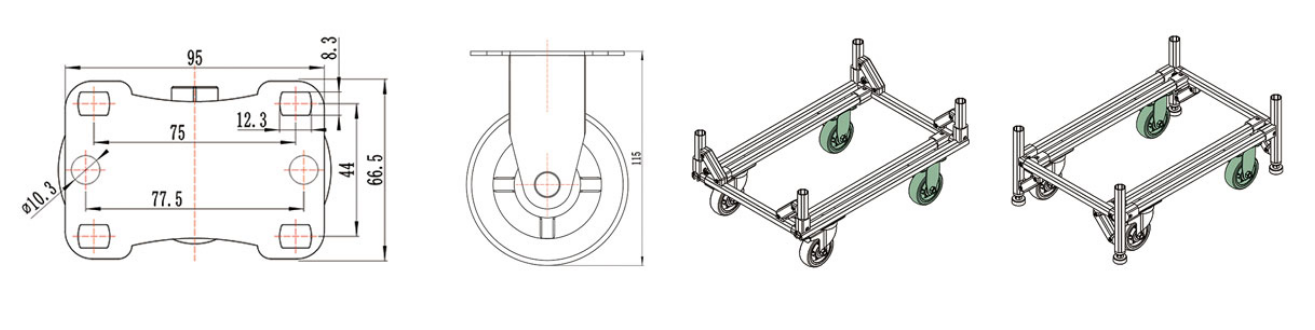

1. The caster of the universal wheel is loose or stuck, which will cause the "grinding point" to be checked and repaired regularly, especially the tightness of the bolt and the amount of lubricating oil. The rolling performance and rotation flexibility of the equipment can be improved by replacing the damaged caster.

2. Check whether the wheel bearing is damaged. If the parts are not damaged, they can be reassembled for further use. If the wheel is often entangled by debris, it is recommended to install a cover plate to avoid.

3. Check whether the bolts and nuts are tightened after checking and repairing the wheels. Try using lock washers or lock nuts on all bolts. If the bolts are loose, tighten them immediately. If the wheel in the bracket comes loose, the wheel will be damaged or unable to turn.

4. Serious damage or loosening of rubber tires may lead to rolling instability, abnormal leakage load, floor damage, etc. Timely replacement of damaged tires and bearings can reduce the cost loss caused by caster damage and shutdown.

5. Regular inspection and maintenance, regularly add lubricating oil caster and bearings, and add lubricating oil friction prone to occur, until there is a small threshold, such as wheel core, thrust washer, roller bearing roller surface, can reduce friction, rotation is more flexible and more convenient to use.