First, eliminate overload

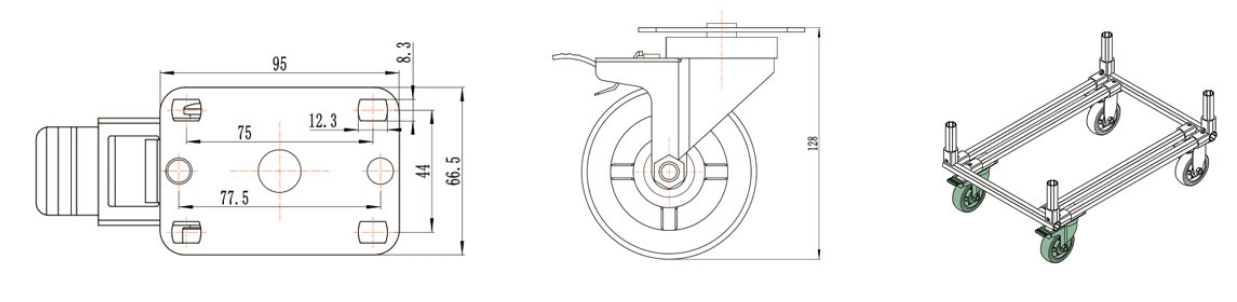

When using the product, users should recognize the carrying weight of casters and supporting products, and choose the appropriate heavy-duty casters to use.

Before use, the weight of the load should be estimated in advance, and the weight of casters and casters supporting products should be more than 1.5 times of the load.

Two, choose casters of different materials for different places of use

Different materials have different physical and chemical properties. Casters of different materials require different environments, of course, the service life of casters will be different.

When using casters, users should be clear about the suitable place to use casters to avoid unnecessary losses caused by misuse.

Three, effective maintenance of casters

Users should regularly maintain the running part of casters.

Iv. Maintenance is divided into three aspects: adding lubricating oil, removing entanglement in the running part and preventing rust.

1. Lubricating oil should be regularly added to the running part of caster's support steel ball and wheel's bearing.

2. Regularly clean the winding or thread head wound in the running part of the steel ball bracket of the caster and the cloud installation part of the wheel bearing;

3. Most casters are made of metal. Anti-rust is very important for the service life of casters.