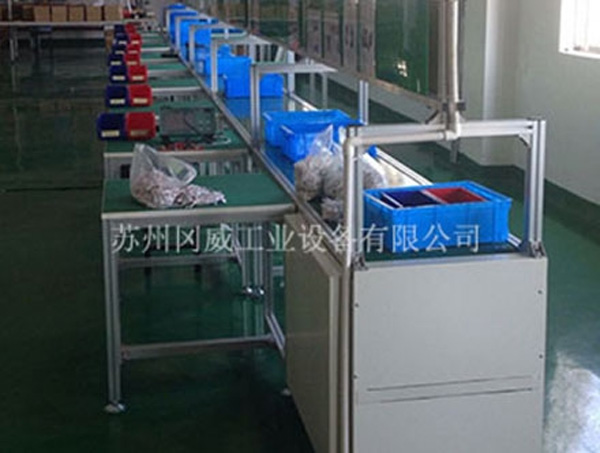

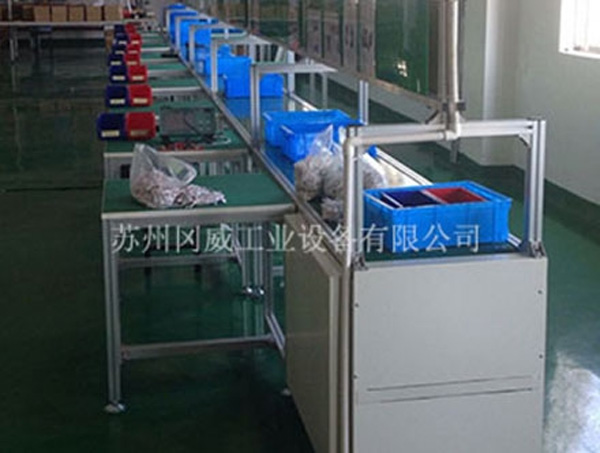

With the improvement of science and technology, the adoption of new technology and new equipment also requires us to adjust the layout of old assembly line equipment. Therefore, the feasibility of factory development and transformation should be considered in the graphic design, and the layout of belt line equipment should have authenticity, adaptability and universality.

1. The product. The design of product structure and device process is the primary focus of pipeline equipment design. The analysis and study of product structure can greatly simplify the process of plant production.

2. Equipment. The selection of plant process equipment is determined according to product technical requirements and plant process method. Accurate selection of process equipment and tooling can not only improve production compliance, reduce manufacturing costs, but also rationalize the layout of assembly line equipment. Topics to be considered when selecting process equipment include: product production program; Product quality requirements; The ancestry of equipment; Equipment reliability; The price of equipment; Operation rate of equipment; Safety of equipment; Ease of maintenance of equipment.

3. The personnel. Human is one of the factors of production, but also a living factor, and mobility, need to be trained to adapt to the job requirements. When the assembly line equipment is arranged, safe working conditions should be considered to create a better working environment, which is conducive to improving the enthusiasm of labor.

4. Logistics and Transportation. Material flow is accomplished by transportation. Transportation of materials is indispensable in the factory, we should choose economical and reasonable transportation mode. A concept can be drawn: the amount of material movement depends on its production factors. The layout of assembly line equipment must ensure that the material flow distance Z is short, and always flow to the end of the product device, and establish a control system to ensure the flow of material.

5. Production practices. Production style is a necessary consideration in the design of assembly line equipment. To determine the production style, the following points should be made clear: production program; Working system, here refers to working shifts and working hours of each shift; Production line type, we should consider the use of active line or old line production, is single production or old machine group production; Management system refers to the management methods, systems and provisions stipulated for ensuring production.

6. Storage and auxiliary facilities. The material flow always flows towards the end of the installation process, but whenever the material stops, there will be a stoppage waiting for material. Therefore, it is necessary to maintain a certain amount of stock in order to ensure the flow of materials, which is economically reasonable in terms of maintaining production and balancing process capacity. To solve the storage problem, it is necessary to establish the necessary storage warehouses and storage sites. In addition, auxiliary equipment for production to provide maintenance and services, also play an important role in production.