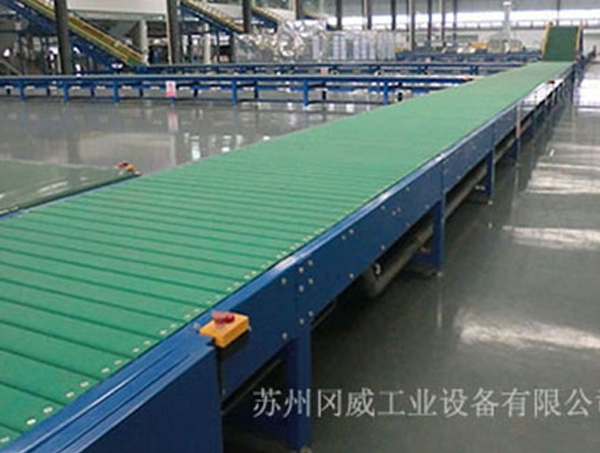

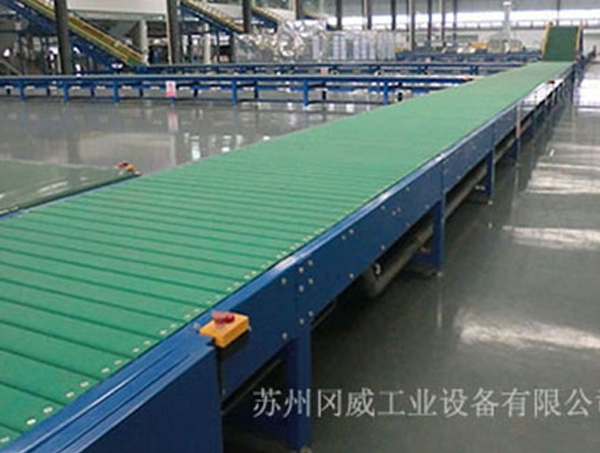

Chain plate line conveying line can bear large load and long distance conveying; The line body form is straight line, turning conveying; Chain plate width can be designed according to customer or actual situation. Chain plate form for straight chain plate, turning chain plate. The main structure is made of carbon steel sprayed or galvanized, and the clean room and food industry is made of stainless steel. Chain plate conveyor line is widely used in diesel engine, household appliances, food, automobile, motorcycle, engine, and other industries of assembly and transportation.

Chain plate line conveyor line, the use of fixed in the traction chain of a series of chain plate in the horizontal or inclined direction of conveying material conveyor line, with a single plate hinged into a ring belt as a transport plane of traction and bearing components bearing surface with transverse spacer placed in the tank to drive the ring belt by spacer scraping coal transport. It consists of driving mechanism, tensioning device, traction chain, lath, driving and reversing sprocket, frame and other parts. It has been widely used in metallurgy, coal, chemical industry, electric power, machinery manufacturing and other industrial sectors of the national economy.

First, the characteristics of chain plate conveyor line: wide range of application. In addition to the viscosity of particularly large materials, general solid materials and components can be used to transport it; Large conveying capacity; The strength of the traction chain is high, which can be used for long-distance transportation. The layout of conveying water line is flexible. Compared with net belt conveyor line, chain plate conveyor line can be transported under the condition of larger inclination Angle and smaller bending radius, so the flexibility of the layout is greater. The dip Angle of chain plate conveyor line can reach 30°-35°, and the bending radius is generally about 5-8m. In the conveying process can be classified, dry, cooling or assembly and other processes; The operation is stable and reliable.

Two, the classification of chain plate conveyor line: the structure of the chain plate conveyor line is diverse. According to the driving mode, it can be divided into electric mechanical driving type and hydraulic driving type. According to the transmission line installation form can be divided into fixed and mobile; According to the layout of the conveying line can be divided into horizontal, horizontal - tilt type, tilt type, tilt - level, horizontal - tilt - level; According to the structure type of the traction member, it can be divided into sleeve roller chain, stamping chain, casting chain, ring chain and removable chain, etc. According to the number of traction chain can be divided into single chain and double chain; According to the structure of the bottom plate can be divided into scale plate and flat plate according to the operation characteristics of the transmission line can be divided into continuous type and pulsation type.